Pioneers set sail with cutting-edge augmented reality applications

Augmented reality apps in the Navy

Though still in its infancy, companies like Newport News Shipbuilding are pioneering ways to exploit augmented reality applications to transform the way they develop, produce and maintain products. Index AR Solutions, which is working with Newport News Shipbuilding and others on the design of custom AR applications, projects the U.S. enterprise market for AR reaching $105 billion within 15 years, including $49 billion spent on hardware, $11 billion on software and $45 billion on services.

The technology is really a breakthrough communications medium, contended Dexter Lilley, COO of Index AR Solutions, which was founded by former executives from the shipbuilding company. “It’s like the difference between having a TV and not having a TV,” he said. “It’s a new communications medium that allows people to see things in 3D before they’re there or walk around something. That’s the leap.”

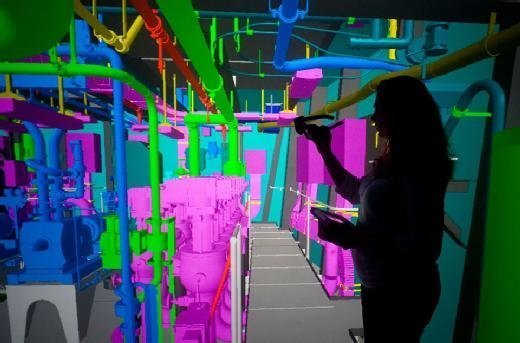

One of the primary ways Newport News Shipbuilding is using AR is to replace drawings and paperwork packages. In one example, the company worked with Index AR Solutions to develop an AR tool that would eliminate reliance on stacks of drawings to locate the temporary steel — nearly 100 tons of it –used during the construction of the aircraft carrier. By digitalizing the ship’s blueprints and using a custom-developed augmented reality app built by the partners on PTC’s Vuforia AR platform, shipyard workers can now easily identify the temporary steel that needs to be removed just by walking around using a tablet. The AR app color codes the temporary structures as green while permanent steel and foundations are displayed in other colors, which allows the steel that needs to be removed to be identified quickly and easily, Lilley said.

“Now they walk into the space, access the 3D marker and look around the ship, and the temporary steel shows up in green,” Lilley explained. “We took 36 hours of work and did it in 90 minutes.”